OilGas Engineers

PROFESSIONAL SUMMARY

Twenty-Seven (27) years of experience in oil and gas/refinery/petrochemical process/project design, technical service, research and process development, pilot testing and scale-up, project management. Worked on units such as LNG production, natural gas amine desulfurization, TEG and molecular sieve dehydration, cryogenic gas plant, gas and oil gathering/separation, LPG/NGL recovery, Clause sulfur recovery, helium separation, flare and blowdown system, tank farm, utility units, bitumen SAGD, crude and vacuum fractionation, fluid catalytic cracking, propylene oxide, propylene glycol, polyether polyol, CNG, etc. Work scope included process selection, optimization, conceptual design, feasibility study, front-end design, detailed design, commissioning and start-up. New and revamp projects onshore and offshore. Involved in the cost estimate in various project stages. Proficient in process simulation, evaluation, heat and material balance, PFD and P&ID, system design, pipe sizing, equipment sizing and selection, flare system and PSV sizing, emission control, Line Designation Table, mechanical and instrumentation specification, safety review, PHA/HAZOP and SIL analysis, cause and effect diagram. Familiar with API and ASME codes, Shell standards and engineering practice.

WORK EXPERIENCE

2008 – 2009 Process Engineer

KBR, Inc. Houston, Texas, USA

Ras Tanura Integrated Project – Saudi Aramco and Dow Chemical – FEED of a refinery and petrochemicals complex. Involved in the process designs of the Propylene Oxide unit, Polyether Polyol units, Propylene Glycol units and utility systems.

2005 – 2008 Senior Process Engineer

WorleyParsons, Calgary, Alberta, Canada

- Long Lake South Phase 1 SAGD Project – Nexen Inc. – Detailed design. Review and optimize flare system design, determine tank farm operation mode and evaluate tank farm design, evaluate slug problem for HP steam and bitumen flowlines with Pipeflow software, review fuel gas, instrument air system, utility steam, water supply, review PFD, P&ID, mechanical and instrument datasheet, calculations. Participated in HAZOP and SIL reviews.

- Findley Gas Plant Project – Talisman Energy Canada – FEED and detailed design. Reviewed amine unit process package from the vendor, designed TEG gas dehydration unit including process simulation, development of PFD, P&ID, heat and material balance, equipment and instrument sizing/datasheets. Analyzed plant flare load and sized flare system with Flarenet. Sized fuel gas and instrument air system.

- Alternative Fuel Study – Husky Energy Inc.– Process study for using heavy oil and bitumen to replace natural gas fuel in the steam boiler for bitumen production. Compared flue gas de-sulfur and bitumen gasification processes. Evaluated bitumen burning technologies. Estimated major equipment sizes and project cost.

- Parsons Lake North Pad Development Project– ConocoPhillips Canada (North) Limited – Preliminary design of good pads and gas conditioning facility in an anchor field of Mackenzie Gas Pipeline. Studied CO2 removing process. Evaluate economics and greenhouse gas emission of CO2 injection and venting process. Developed process specification for water treatment facilities, waste incinerator, and potable water treatment facility. Estimated equipment and project cost for different production capacity cases.

- Mackenzie Gas Project – Imperial Oil Resources Ventures Limited – Gate 3 (preliminary) level process design and cost estimate of the Inuvik Gas Processing Facility feeding the Mackenzie Gas Pipeline. Designed relief and blowdown system including Dynsim dynamic analysis of flare system MDMT for correct material selection and cost saving. Solved issues from HAZOP review. Reviewed P&ID, process calculations, mechanical and instrument datasheets.

2001 – 2005 Lead Process Engineer

Colt Engineering Corp, Sarnia, Ontario, Canada

- ULSD OSBL Project – Shell Canada – Established process basis of de-sign, leading design kickoff and PFD review. Performed refinery configuration studies for processing Ultra Low Sulfur Diesel. Defined revamp scope in crude units, tank farm, rundown and transfer pipeline. Reviewed P&ID, LDT, datasheet.

- New Flare System Project – Shell Canada – Replaced the refinery flare system including flare stack, seal drum, Main and unit flare headers, knock-out drums, slop system, pumps, relief valves. Activities included visualflow simulation, P&ID, equipment and instrument datasheet, LDT development. Participated in capacity, reliability, HAZOP(safeguarding) and SIL review.

Senior Process Engineer

Colt Engineering Corp, Sarnia, Ontario, Canada

- Gasoline Desulphurizer Project – Suncor Energy Products – Performed Hydraulic calculation for the H2 pipeline.

- Port Stanley Gas Plant PSV Study – Talisman Energy Canada– Studied gas plant relief system capacity and recommended revamp scope.

- Gasoline Hydrotreater OSBL Project – Shell Canada – Designed Hydrogen Chloride Absorber. Developed PFD, P&ID, LDT, equipment and instrument datasheets.

- Flare System Modification Project– BP Canada – Designed area flare header and relief valves for propane & butane bullets. Performed flare header and PSV sizing.

- Warm Water Loop Project – Shell Canada – Designed pump, exchanger and pipeline for energy recovery from crude fractionation tower. Completed pump and exchanger sizing.

- FCCU Air Pre-heater Burner Management System – Shell Canada – Designed a new fuel gas system and burner management system for an air pre-heater in FCCU regenerator. Participate in HAZOP (safeguarding) and SIL review.

1997 – 2001 Project Manager/Process Engineer

Maloney Industries Inc, Calgary, Alberta, Canada

- TEG Gas Dehydration Projects – Commissioning/start-up support, troubleshooting, technical service for 21 skids mounted TEG units in 7 projects, onshore or offshore.

- Molecular Sieve Dehydrators – Coordinated the construction of 3 molecular sieve dehydrators in compressed natural gas (CNG) stations for bus fuel.

- Cryogenic Gas Plant – Project management and technical service for the construction and start-up of a $20 million USD “turnkey” project. Plant included gas engine driven compressors, molecular sieve dehydrators, propane refrigeration system, NGL fractionation. Wrote an operation guide and trained engineers/operators for the client.

- Cryogenic (JT) Dehydration Unit – Technical support for installation and start-up of a JT unit including methanol injection, JT valve, gas/gas exchangers and separators.

- Oil Battery – Pre-commissioning, commissioning of an oil battery including oil heat treaters, 3 phase separators, utility units, etc. in Tarim Desert.

1989 – 1997 Senior/Lead/ Process Engineer

Sichuan Petroleum Design Institute, CNPC, China

- LNG Production Plant – Lead process engineer in the conceptual design and pre-feasibility study of an LNG production plant- a billion USD project with 60 million m3/d (2100 MMSCFD) natural gas liquefaction capacity. Evaluated natural gas liquefaction and regasification process from JGC and Linde AG. Involved in the selection of compressor, turbine and LNG storage tanks. Supported the overall project cost estimate.

- LPG Desulfurization Project – Kuwait National Refinery – Lead process engineer in technical bid preparation for molecular sieve LPG desulfurization units.

- Gas Desulphurization Plant – Senior process engineer in the detailed design of an Amine treating plant. 800,000 m3/d (28 MMSCFD) gas treating capacity.

- Cryogenic Gas Plant – Lead process engineer in a grassroots cryogenic (turboexpander) gas plant. Worked through all project phases including conceptual design, feasibility study, preliminary and detailed design, construction, and commissioning/startup.

- Sulfur Recovery Plant – Process engineer in the detailed design of a MCRC Sulfur Recovery Plant based on process package provided by Delta Hudson Engineering Ltd.

- Helium Separation Plant – Process engineer in the feasibility study of a Helium separation plant.

- He Nan Refinery Revamp Project – Process engineer in the detailed design of a Residual Oil Catalytic Cracking Unit (FCCU) revamp project.

EDUCATION

B.S., Petroleum Process Engineering

1983 East China Petroleum Institute, Shandong, China

M.S., Chemical Engineering

1989 University of Petroleum, Beijing, China

REGISTRATIONS/AFFILIATIONS

- Licensed Professional Engineer, Alberta

- Licensed Professional Engineer, Ontario

PUBLICATIONS/PRESENTATIONS

- Investigation of Mid-Scale Residual Oil Catalytic Cracking Units for Continuous Operations in China. The 2nd Anniversary Academic Conference of the Oil and Gas Processing Association. 1991. China.

- How a Catalytic Cracking Process is affected by the Composition & Properties of the Residual Oil Feedstock. Postgraduate Thesis.

- Abstract Asphalt from Residual Oil by Supercritical Fluid. Graduate Thesis. 1983.

SPECIFIC TECHNICAL EXPERTISE/SPECIALIST COURSES

- Petro-Sim

- Hysys

- Aspen

- PRO-II

- Amsim

- Sulsim

- Visualflow

- Flarenet

- Dynsim

- HTRI

- TASC

- ACOL

- Pipeflow

Showing 1–12 of 31 results

-

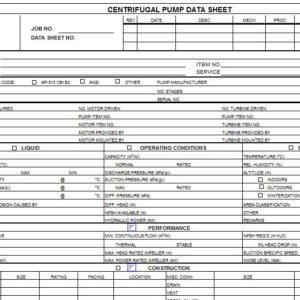

CENTRIFUGAL PUMP DATASHEET 01

$3,600.00 Add to cart -

Centrifugal Pump Datasheet Review

$1,600.00 Add to cart -

Centrifugal Pump Datasheet Template

$0.00 Add to cart -

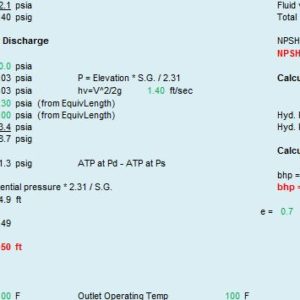

Centrifugal Pump Sizing 01

$3,000.00 Add to cart -

Centrifugal Pump Sizing Mentoring

$600.00 Read more -

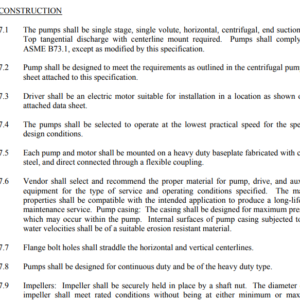

Centrifugal Pump Specifications

$9,800.00 Add to cart -

Centrifugal Pump Troubleshooting Help

$2,000.00 Add to cart -

Chemical Engineer for Hire

From: $120.00 Select options -

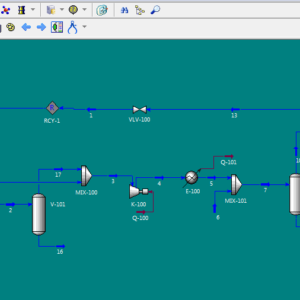

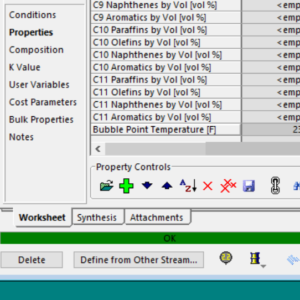

Chemical Process Simulation

$8,000.00 Add to cart -

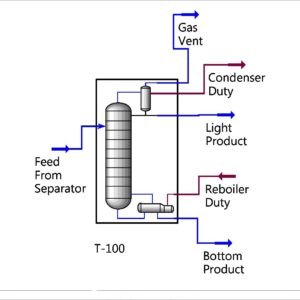

Distillation Column Sizing 01

$5,000.00 Add to cart -

Fluid Specific Gravity Calculation Services

$120.00 Select options -

Fluid Vapor Pressure Calculation Services

$280.00 Select options

Showing 1–12 of 31 results