Use pump sizing calculator below to calculate required data for pump purchase, etc. Click on COST ESTIMATE button at bottom to obtain pump cost estimate.

PUMP SIZING CALCULATOR INSTRUCTION

The pump sizing calculator was developed by OilGas engineers, a professional engineer and pump expert. It is the best tool for pump station design and pump troubleshooting. The calculator includes three sections:

- NPSH available calculation

- Pump discharge pressure calculation

- Pump power calculation

To perform pump sizing calculation, simple input the fluid data and the piping system information in the calculator form. The calculation results will be shown in the form immediately. For your convenience the fields with white background are input fields. The fields with gray background are results fields. The key calculation results are highlighted in blue color.

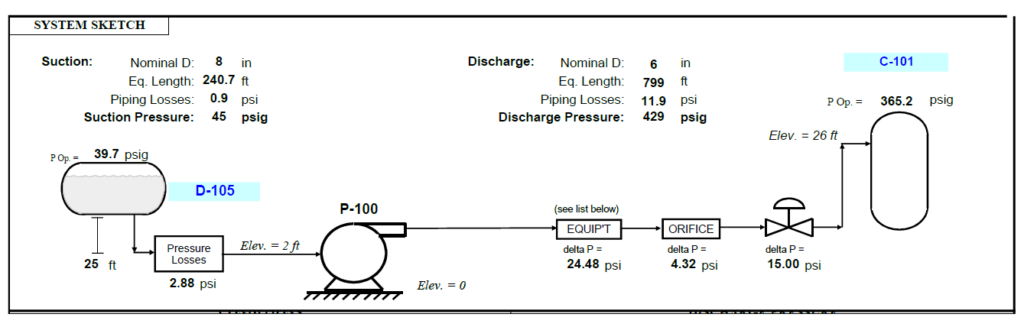

Correct input have to be provided in order to get a correct pump sizing results. Below is a typical pumping system sketch to help you understand the input data and calculation results. If you have any questions, please contact OilGas engineers for help.

HOW TO OBTAIN REQUIRED INPUT DATA

FLUID CONDITIONS

If you can’t find some of the fluid data such as specific gravity, viscosity, vapor pressure and so on, please contact us by clicking below button, we will help you find the data and assist you to complete your calculation.

PIPING LOSSES

Piping Losses can be calculated with the Pipe Pressure Drop Calculator by clicking the button below.

CONTROL VALVE LOSSES

To have the control valve working properly, the pressure drop across the control valve can not be too low. As a rule of thumb, 25 to 33% (1/3rd) of the total system pressure drop (including the valve) is taken across the control valve, with a minimum of 10-15 psig.

PUMP SELECTION & TROUBLESHOOTING

To ensure the pump working properly:

- The pump’s NPSH requirement have to be less than the NPSH available calculated from the Pump Sizing Calculator.

- At the same time pump’s TDH (total dynamic head) has to be higher than the TDH calculated from the Calculator.

- In addition pump motor’s horsepower much be higher than the brake power calculated from the Pump Sizing Calculator.