Description

Our NPSH Calculation & Pump Sizing Services

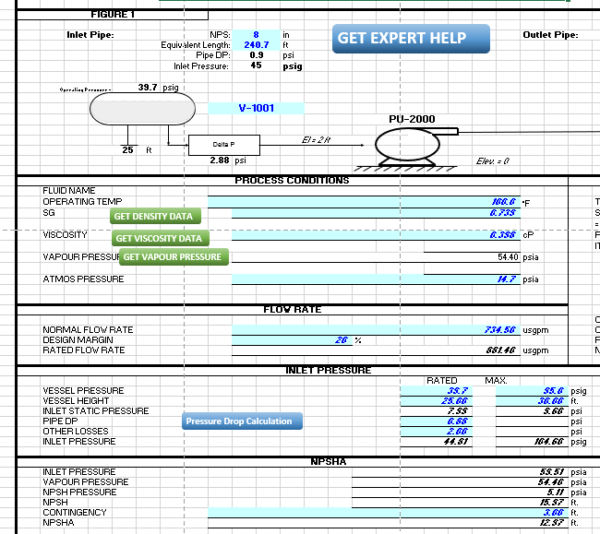

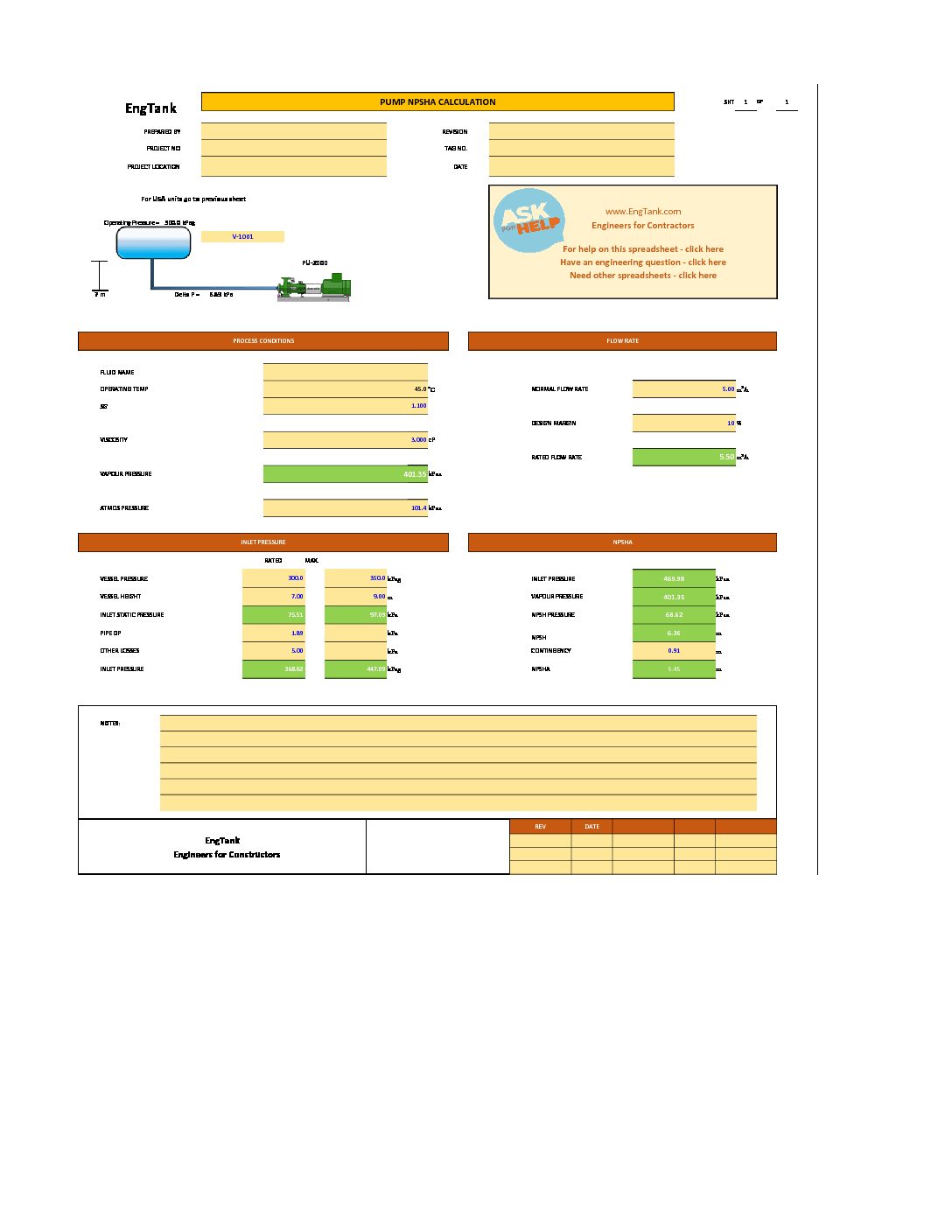

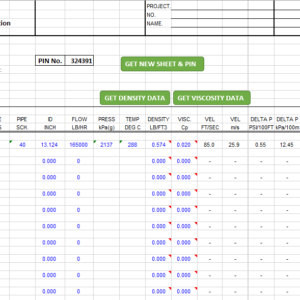

NPSH calculation and pump sizing are crucial for selecting the right pump. Accurate calculations can ensure optimal pump performance and prevent cavitation and damage. However, if you don’t have enough time to perform the calculations using a spreadsheet, our pump experts can assist you. With over 20 years of experience in centrifugal pump sizing and NPSH calculations, our experts understand how centrifugal pumps work and why they may not work. Consequently, with our help, you’ll be able to select the best pump for your application, saving you time and project costs. So, click the button below to get started.

Other NPSH Calculation & Pump Sizing Spreadsheet

Profile of OilGas Engineer

SUMMARY

- Twenty-Seven (27) years of experience in oil & gas /refinery /petrochemical process/project design, technical service, research and process development, pilot testing and scale-up, project management.

- Worked on units such as LNG production, natural gas amine desulfurization, TEG & molecular sieve dehydration, cryogenic gas plant, gas and oil gathering/ separation, LPG/NGL recovery, Clause sulfur recovery, helium separation, flare and blowdown system, tank farm, utility units, bitumen SAGD, crude and vacuum fractionation, fluid catalytic cracking, propylene oxide, propylene glycol, polyether polyol, CNG, etc.

- Work scope included process selection, optimization, conceptual design, feasibility study, front-end design, detailed design, commissioning and start-up. New and revamp projects onshore and offshore. Involved in cost estimate in various project stages.

- proficient in process simulation, evaluation, heat & material balance, PFD and P&ID, system design, pipe sizing, equipment sizing and selection, flare system and PSV sizing, emission control, Line Designation Table, mechanical & instrumentation specification, safety review, PHA/HAZOP & SIL analysis, cause & effect diagram.

- Familiar with API and ASME codes, Shell, Exxon Mobil, BP standards and engineering practice.

EXPERIENCE

2008-2009 Process Engineer – KBR, Inc. Houston, USA

2005-2008 Senior Process Engineer – WorleyParsons, Calgary, Canada

2001-2005 Lead Process Engineer – Colt Engineering Corp, Sarnia, Canada

Registrations/Affiliations

Licensed Professional Engineer, Alberta, Canada

Licensed Professional Engineer, Ontario, Canada

Specific Technical Expertise/Specialist Courses

Advanced level in Petro-SIM, Hysys, Aspen, PRO-II, Amsim, Sulsim, Visualflow, Flarenet, Dynsim, HTRI, TASC, ACOL, Pipeflo.

Reviews

There are no reviews yet.